A variety of consulting services are provided by Tarmac, including MECHANICAL AND ELECTRICAL installation, COMMISSIONING, and training.

These services are available for all makes and models of thermal drying plants, screening, crushing, storage, and also air pollution control and electrical systems.

INSTALLATION SERVICE

Watch this Tarmac Industrial Plant Installation. This includes supervisors, crews, and cranes available for hire. It can be time-consuming to find installation equipment and crews. A Tarmac supervisor leads our Installation and Service Department and therefore can make the process faster and at a reduced cost for you.

See Details About Tarmac's Service Work

Take Down & Relocation

Take down and relocation service can include cranes, trucks, and laborers. Let Tarmac handle the details, whether you are the buyer or seller.

combustion Analysis

Includes study of dryer rotational speed, flight material quality, veiling efficiency, burner CO output, air leakage, and methods to reduce gas discharge temperatures.

AIR POLLUTION CONTROL REVIEW

We study the pressure drop across your full system. This includes duct sizing, primary collectors, baghouse and ID fan sizing, and all associated instruments.

Trunnion Alignment

Trunnion Alignment is a necessary part of routine maintenance. Tarmac service people check each trunnion for alignment and surface contact. Poor trunnion adjustment can cause thrust roller and bearings to catastrophically fail. Catch problems and fix them before you have a failure that shuts down production.

Operation Training

Available at your site or at our office. This can be particularly helpful while waiting on the arrival of a new system.

Mass Balance Studies

A sales engineer inputs the variables of using a rotary dryer for a particular project, such as:

- Input tons per hour

- Moisture to be removed

- Elevation

- The specific heat of the product

- Output material temperature

- and output gas temperature.

Then the mass balance spreadsheet calculates the requirements of the drying plant which includes choosing the diameter of the dryer, size of the burner, and gas flow volume in ACFM for the baghouse and ID fan size. The mass balance can confirm the ideal:

- Diameter and length of the dryer

- Size of burner

- Size of cyclone

- Size of baghouse

- and the fan.

These values are then compared to what is at the job site we visit, and suggestions are made for improvement. Your salesperson will help you prioritize the findings and help you plan your improvements accordingly.

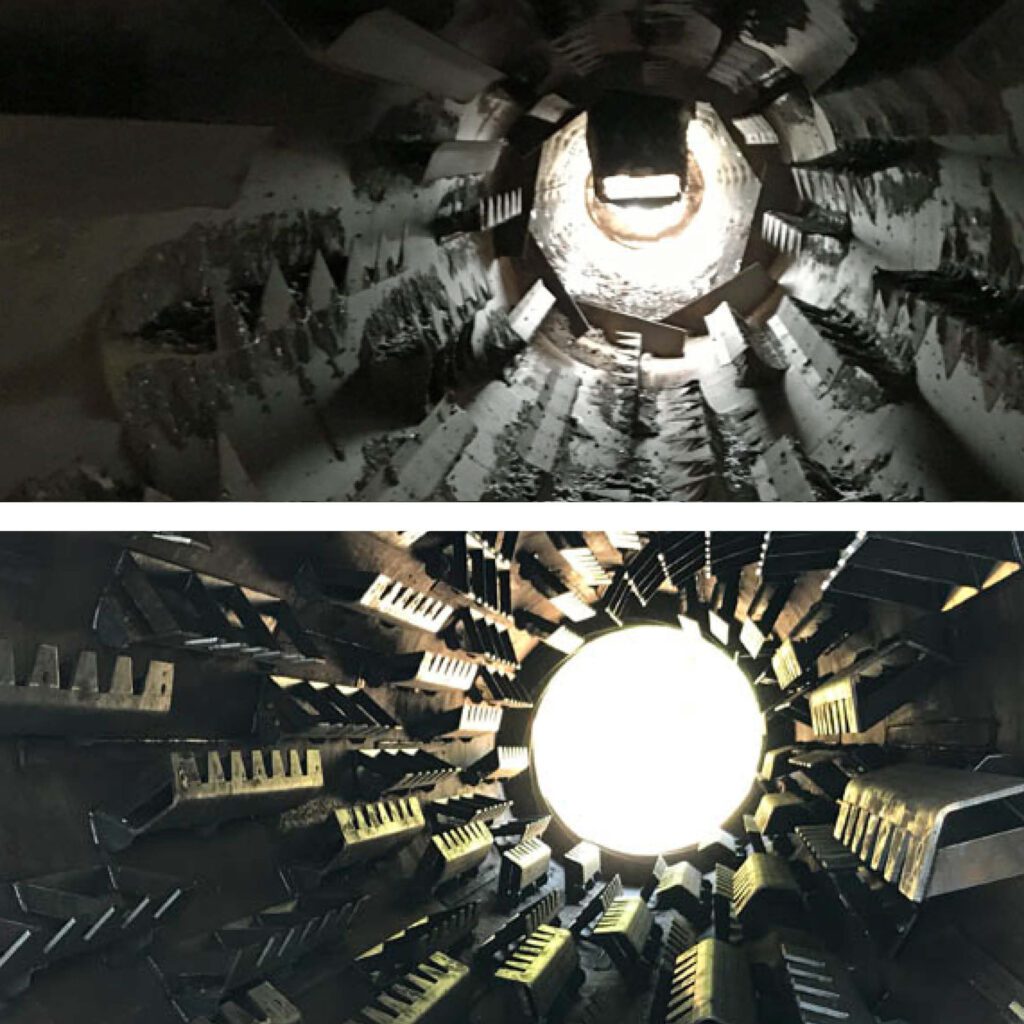

RECONDITIONING

Reconditioning can be a cost-effective way for a plant upgrade. Buy a used piece of equipment and let Tarmac recondition it for you. HERE is a post showcasing how dramatic, and certainly, how worthwhile this can be.

Complete Plant Consumption Review

Study includes balancing the whole plant for production and efficiency in addition to the reviews above.

Consulting Services Can Help Your Plant Run Better

Get In touch

Is there a problem you need us to troubleshoot? We can help find a solution. Contact us for our current rate sheet for consulting service. Tell us what you are looking for!

Contact Tarmac