Control Design,

Our team’s commitment to control design and fabrication reduces time from order to installation/commissioning. Tarmac International, Inc. provides complete drying, screening, size reduction, and storage plant systems for a variety of industries. Tarmac’s commitment is to be a single source, responsible for equipment and control systems. We complete these before they arrive at the job site for rapid installation.

Understanding the Connections

Tarmac understands the function of all the equipment. The connection is vital between the feed bins, dryer, burner and fuel package, air pollution control, screening and material reduction, and silo storage and loadout. If a company is providing electrical equipment, wiring, PLC, and/or installation without knowledge of the mechanical equipment and how instruments interact in the field, there will, therefore, be a long delay in commissioning the plant. We build the complete Control Center, purchase power wire and instrument wire, and finalize programming the PLC system before shipping.

Robust Control Centers with Robust Control Design

The control system begins with the Control Center which is a robust tubular steel and steel channel frame building. We design our Control Center’s Starters, VFDs, Main Breaker, and Transformer and mount them. Engineers review designs to assure the structural integrity of the steel framing to support this equipment and additionally allow for crane lifting of this load for transportation and setting the Control Center at the final plant site. The operator is in the front of the building with windows on three sides. Starters/VFDs run in the rear of the building. A 3 or 5 ton air/heating unit is included so the building climate controlled.

Pre-wiring and Pre-programing

Starters can be provided within either MCC buckets or mounted within NEMA 12 panels. Sealed enclosures exiting the rear of the building insure ease of access to all field connections. The PLC IO enclosure is mounted within the starter panels and pre-wired. This allows the PLC to interface via a single ethernet cable with the PLC HMI screens, keyboard, and mouse, in the front control room. Our electricians pre-program the PLC before it is sent to the job site. The Tarmac supplied Control Center is completed at the shop and not at the customer’s job site. This is in order to shorten the time period for plant commissioning.

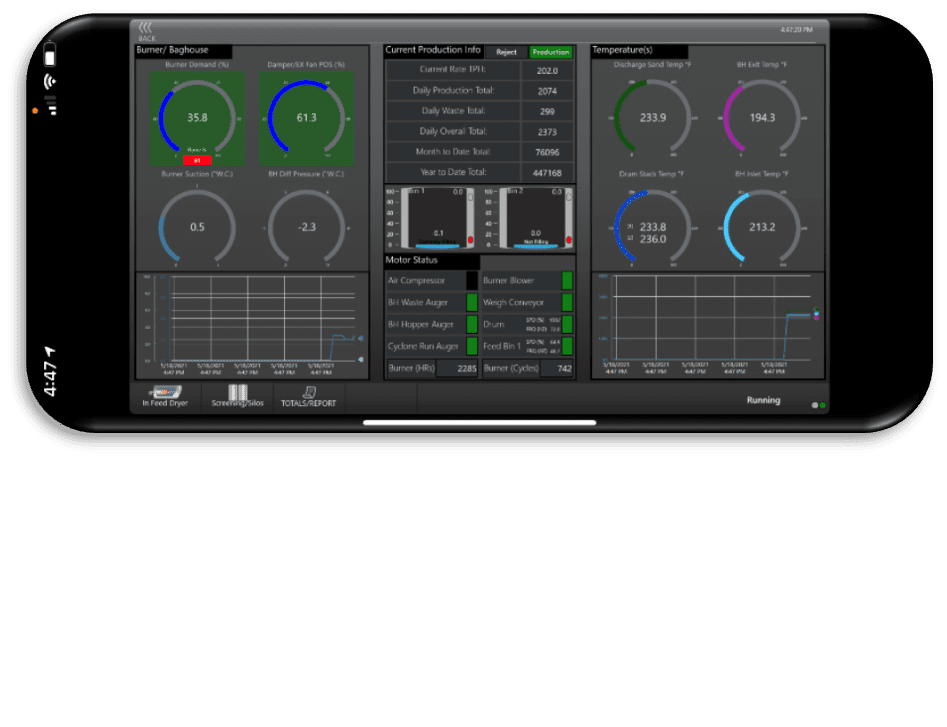

The PLC not only offers interlocking of the motors, instruments, loadout, and Burner Management System, but provides to the operator our customer’s management team trending data: production rates, types of material run, temperatures, and upset conditions. Often managers want to see how the plant is running day or night. To this end a “Dash Board” feature gives a snap shot of the plant in a real time on any smart device. In addition, Tarmac electrical service personnel can access the PLC online to provide trouble shooting or update programming.

Wiring

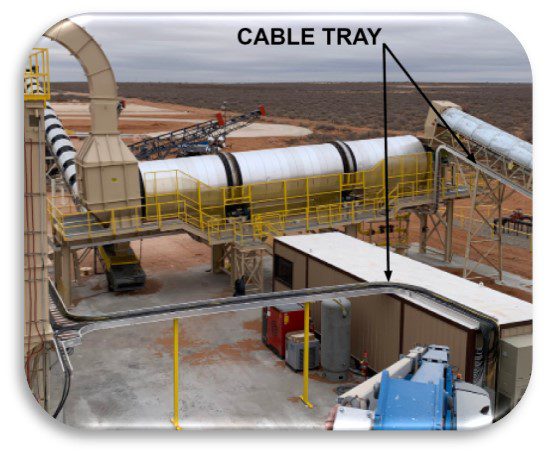

Installation of power and instrument wires from the Control Center to the motors and instruments can be within conduit or supported by cable tray. Where shielded wires are required, Tarmac correctly sources the correct wire to improve signal integrity, for example, on sensitive burner instruments, belt scales, and thermocouples. Burner control wiring and fuel train components are specifically troublesome for our customers that attempt burner installation themselves. Your installation is easier and faster using our trained installers, especially for:

- Plumbing and wiring the fuel train

- Installing the wires in the burner J box

- Wiring the Burner Management System (BMS) within the Control Center

- and tuning the efficiency and emissions from the burner

The photo below shows a pre-assembled fuel train after being located and wired in Florida. The photo to the right shows typical cable tray. Notice the power wire terminating into the rear junction box of the Control Center.

Robust Controls Designed for Quicker Installation

In conclusion, Tarmac International, Inc. designs a robust Control Center. Pre-wired starters/VFDs and pre-programmed PLC move any project forward resulting in fewer days of installation. Additionally, installation service is available to bring the system on line, CLICK HERE to start that conversation.